Milestone-Proposal:Matsukawa Geothermal Power Plant, 1966

To see comments, or add a comment to this discussion, click here.

Docket #:2025-22

This proposal has been submitted for review.

To the proposer’s knowledge, is this achievement subject to litigation? No

Is the achievement you are proposing more than 25 years old? Yes

Is the achievement you are proposing within IEEE’s designated fields as defined by IEEE Bylaw I-104.11, namely: Engineering, Computer Sciences and Information Technology, Physical Sciences, Biological and Medical Sciences, Mathematics, Technical Communications, Education, Management, and Law and Policy. Yes

Did the achievement provide a meaningful benefit for humanity? Yes

Was it of at least regional importance? Yes

Has an IEEE Organizational Unit agreed to pay for the milestone plaque(s)? Yes

Has the IEEE Section(s) in which the plaque(s) will be located agreed to arrange the dedication ceremony? Yes

Has the IEEE Section in which the milestone is located agreed to take responsibility for the plaque after it is dedicated? Yes

Has the owner of the site agreed to have it designated as an IEEE Milestone? Yes

Year or range of years in which the achievement occurred:

1966

Title of the proposed milestone:

First Commercial Geothermal Power Plant in Japan, 1966

Plaque citation summarizing the achievement and its significance; if personal name(s) are included, such name(s) must follow the achievement itself in the citation wording: Text absolutely limited by plaque dimensions to 70 words; 60 is preferable for aesthetic reasons.

Matsukawa Geothermal Power Plant, constructed in 1966 by Japan Metals & Chemicals Co., Ltd. with support from domestic manufacturers, has been continuously operated by the Tohoku Electric Power Group. As Japan’s first commercial geothermal facility, its technical achievements and operational experience have significantly influenced geothermal development across the country and informed the design and construction of geothermal plants internationally.

200-250 word abstract describing the significance of the technical achievement being proposed, the person(s) involved, historical context, humanitarian and social impact, as well as any possible controversies the advocate might need to review.

The Matsukawa Geothermal Power Plant, commissioned in 1966, is Japan’s first commercial geothermal facility and the earliest of its kind in Asia. Built in the Hachimantai Plateau of Iwate Prefecture, the plant overcame significant technical, political, and geographical challenges to become a model of renewable energy development. Engineers successfully adapted dry steam technology—first pioneered in Italy and the United States—to Japan’s unique geological conditions, innovating turbine designs and corrosion-resistant materials to manage low-pressure, gas-rich steam reservoirs.

The plant’s location within Towada-Hachimantai National Park required environmental safeguards and community engagement, establishing a model for sustainable development within environmentally protected regions. Unlike earlier geothermal plants abroad, Matsukawa integrated its operations with regional agriculture and tourism, repurposing geothermal byproducts for hot spring facilities and greenhouse heating.

Matsukawa’s success demonstrated the feasibility of geothermal energy in Japan’s volatile terrain and influenced national energy policy, especially after the 2011 Fukushima disaster. Recognized as a Mechanical Engineering Heritage site in 2016, it continues to serve as an educational hub and a symbol of innovation, safety, and resilience. Its enduring performance over five decades underscores its legacy and impact, inspiring subsequent geothermal initiatives across Japan and Asia.

Its sustained operation for over five decades and its contributions to science, policy, and international collaboration make it a fitting recipient of the IEEE Milestone recognition.

IEEE technical societies and technical councils within whose fields of interest the Milestone proposal resides.

IEEE Power & Energy Society (PES)

IEEE Power Electronics Society (PELS)

In what IEEE section(s) does it reside?

IEEE Sendai section

IEEE Organizational Unit(s) which have agreed to sponsor the Milestone:

IEEE Organizational Unit(s) paying for milestone plaque(s):

Unit: IEEE Sendai Section

Senior Officer Name: Hiroaki Muraoka

IEEE Organizational Unit(s) arranging the dedication ceremony:

Unit: IEEE Sendai Section

Senior Officer Name: Hiroaki Muraoka

IEEE section(s) monitoring the plaque(s):

IEEE Section: IEEE Sendai Section

IEEE Section Chair name: Hiroaki Muraoka

Milestone proposer(s):

Proposer name: Chiaki Ishikawa

Proposer email: Proposer's email masked to public

Proposer name: Hayato Abe

Proposer email: Proposer's email masked to public

Proposer name: Yoshiyuki Ito

Proposer email: Proposer's email masked to public

Proposer name: Koichi Kotanaka

Proposer email: Proposer's email masked to public

Proposer name: Kato Osamu

Proposer email: Proposer's email masked to public

Please note: your email address and contact information will be masked on the website for privacy reasons. Only IEEE History Center Staff will be able to view the email address.

Street address(es) and GPS coordinates in decimal form of the intended milestone plaque site(s):

MATSUKAWA GEOTHERMAL MUSEUM, Matsuo-Yoriki, Hachimantai-shi, Iwate, 028-7302, Japan

GPS Coordinate: 39.8722254,140.9198014,16.77

Photo of MATSUKAWA GEOTHERMAL MUSEUM

Describe briefly the intended site(s) of the milestone plaque(s). The intended site(s) must have a direct connection with the achievement (e.g. where developed, invented, tested, demonstrated, installed, or operated, etc.). A museum where a device or example of the technology is displayed, or the university where the inventor studied, are not, in themselves, sufficient connection for a milestone plaque.

Please give the details of the mounting, i.e. on the outside of the building, in the ground floor entrance hall, on a plinth on the grounds, etc. If visitors to the plaque site will need to go through security, or make an appointment, please give the contact information visitors will need. The plaque will be displayed on an entrance hall of MATSUKAWA GEOTHERMAL MUSEUM.

Are the original buildings extant?

Yes.

Details of the plaque mounting:

The plaque will be displayed an entrance hall of MATSUKAWA GEOTHERMAL MUSEUM.

How is the site protected/secured, and in what ways is it accessible to the public?

Visitors can come to the MATSUKAWA GEOTHERMAL MUSEUM without security check.

Who is the present owner of the site(s)?

Tohoku Sustainable & Renewable Energy Co., Inc.

What is the historical significance of the work (its technological, scientific, or social importance)? If personal names are included in citation, include detailed support at the end of this section preceded by "Justification for Inclusion of Name(s)". (see section 6 of Milestone Guidelines)

Historical Significance of the Matsukawa Geothermal Power Plant

Introduction

Commissioned in 1966 in Iwate Prefecture, Japan, the Matsukawa Geothermal Power Plant is historically significant as the first commercial geothermal facility in Japan and Asia. It represents a pivotal moment in the global adoption of renewable energy and remains a model of technological innovation, sustainability, and environmental integration.

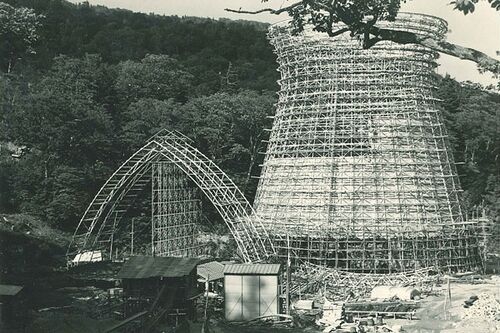

Photo 1 Left: Power generation building; Right: Cooling tower

Photo 2 Assembling the steam turbine

Photo 3 Assembling the generator

Technological Innovation and Pioneering Application

Adoption of Dry Steam Method

The significance of the Matsukawa plant begins with its adoption of the dry steam geothermal power generation method, a process in which high-temperature steam from deep underground reservoirs is directly fed into turbines to generate electricity. This method, though simple in principle, requires exceptionally suitable geological conditions and advanced engineering controls.

Integration with Global Pioneers

Matsukawa’s adoption of the dry steam technique followed pioneering implementations in Italy’s Larderello and the Geysers in California, positioning Japan as an early contributor to global geothermal development.

Engineering Achievements in Japan

The plant was developed in collaboration with Japanese academia and industrial sectors, developing uniquely Japanese innovations in turbine design—such as pressure-adaptive nozzles and anti-corrosion materials—based on field data collected under challenging geological conditions. These innovations directly influenced Japan’s industrial standards in geothermal plant design and monitoring systems.

Scientific Contributions to Geothermal Resource Utilization

Long-Term Geological Insights

The Matsukawa Geothermal Power Plant offered researchers a rare opportunity to gather long-term data on subsurface geothermal systems in a region previously unexplored for power generation. However, the acquisition of reliable geological data in the 1960s posed significant challenges. At the time, Japan lacked advanced downhole sensors and digital monitoring equipment. Temperature and pressure readings were taken manually using mechanical gauges, which required trained personnel to operate under hazardous high-temperature conditions at wellheads.

Moreover, the steam at Matsukawa contained hydrogen sulfide concentrations exceeding 300 ppm level that caused significant corrosion to early turbine materials and piping. Instruments had to be frequently recalibrated or replaced, slowing down research progress and increasing operational costs. Despite these obstacles, engineers and geologists compiled valuable datasets over time, enabling the development of early models for reservoir behavior, steam mineral content, and pressure decline. These empirical insights laid the groundwork for improved reservoir management strategies and future exploration across Japan.

Collaborative Research and Education

Through partnerships with universities and research institutes, the plant served as a “living laboratory,” fostering scientific inquiry and field-based learning.

National Resource Exploration Impact

The success of Matsukawa validated high-enthalpy geothermal zones in Japan, driving nationwide efforts in geothermal exploration and improving technologies for subsurface imaging.

Social and Environmental Importance

Energy Security for Japan

Commissioned during Japan’s post-war industrial expansion, Matsukawa contributed to energy diversification and reduced dependence on imported fossil fuels—an impact amplified in the post-Fukushima energy landscape.

Regional Economic Development

The plant supported the rural Hachimantai region by creating jobs, improving infrastructure, and supplying heat to spas, greenhouses, and aquaculture, demonstrating sustainable community integration.

Ecological Stewardship

At the Matsukawa Geothermal Power Plant, environmental considerations were a key aspect of its operation. Although geothermal brine containing hazardous components was reinjected underground, the plant supplied the warm water generated during the steam utilization process to nearby agricultural facilities. This approach promoted both effective resource use and environmental preservation, while also contributing to regional agricultural development.

Recognition and Enduring Legacy

National Engineering Heritage

In 2016, Matsukawa was named a Mechanical Engineering Heritage site by The Japan Society of Mechanical Engineers (JSME), acknowledging its pioneering role and exceptional operational durability.

Educational and Policy Influence

Its history is featured in academic curricula and professional training programs. It continues to shape national energy policy and inspire future generations of energy engineers and scientists.

Its operational practices and environmental design have been referenced by international geothermal associations, including the International Geothermal Association (IGA), affirming its global relevance."

Catalyst for Domestic and International Geothermal Expansion

The successful operation of the Matsukawa Geothermal Power Plant served as a springboard for Japan's national geothermal energy program. Building upon the technical and operational insights gained at Matsukawa, Japan has since developed over 20 commercial geothermal power stations with a combined installed capacity exceeding 530 megawatts as of 2024. These include prominent plants such as Onuma, Otake, Hatchobaru, and Mori, each incorporating lessons in reservoir management, corrosion control, and turbine optimization pioneered at Matsukawa.

Furthermore, Japan's geothermal engineering expertise, fostered through Matsukawa's legacy, has played a vital role in international cooperation. Japanese firms and researchers have contributed to geothermal development projects in countries such as Indonesia, the Philippines, Kenya, and Mexico—offering support in resource assessment, plant design, and environmental management. This international engagement reflects Matsukawa's broader impact not only on domestic energy diversification but also on the global advancement of sustainable geothermal technology.

Conclusion

The Matsukawa Geothermal Power Plant is historically significant for being one of the earliest commercial geothermal facilities globally and the first in Japan. It exemplifies enduring technological innovation, scientific advancement, and socio-environmental value. Its lasting legacy affirms its candidacy for recognition under the IEEE Milestone program.

What obstacles (technical, political, geographic) needed to be overcome?

Overcoming Obstacles in the Development of the Matsukawa Geothermal Power Plant

The establishment of the Matsukawa Geothermal Power Plant in 1966 marked a pioneering achievement in Japan’s energy history. The project faced considerable technical, political, and geographic challenges that had to be resolved for its successful implementation. The project faced and overcame a complex interplay of technical, political, and geographic obstacles, each of which shaped the plant’s design, implementation, and long-term success.

Technical Challenges

Lack of Precedent and Domestic Expertise

At the time of Matsukawa’s conception, Japan had no prior experience in commercial geothermal power generation. The dry steam method, used successfully in Italy’s Larderello and California’s Geysers, had never been implemented in Japan. Engineers and scientists had to adapt foreign technologies to Japan’s unique geological conditions, often without direct access to proprietary designs or operational data.

Steam Quality and Equipment Durability

The geothermal steam at Matsukawa contained corrosive gases such as hydrogen sulfide, which posed risks to turbine blades and piping systems. Developing materials and coatings that could withstand long-term exposure to these elements required extensive research and testing. The team had to innovate in metallurgy and fluid handling to ensure operational stability and safety.

Reservoir Management and Sustainable Output

Understanding the geothermal reservoir’s behavior was another major hurdle. Without modern modeling tools, engineers relied on empirical data and trial-and-error drilling to locate viable steam sources. Maintaining sustainable output over decades required careful sizing of the plant and conservative extraction strategies, which were not common practice at the time.

Political and Regulatory Barriers

Energy Policy and Institutional Support

In the 1950s and 60s, Japan’s energy policy was heavily focused on coal and hydroelectric power, with emerging interest in nuclear energy. Geothermal was not yet recognized as a strategic resource. Convincing policymakers and utility companies to invest in an unproven technology required persistent advocacy and demonstration of long-term benefits.

Land Use and National Park Restrictions

The Matsukawa site is located within the Towada-Hachimantai National Park, a protected area with strict land-use regulations. Securing permits for drilling and construction involved negotiations with environmental agencies and local governments. The project had to demonstrate minimal ecological impact and incorporate environmental safeguards into its design.

Public Perception and Local Engagement

Geothermal energy was largely unfamiliar to the public, and in Matsukawa, initial drilling was carried out for local hot spring development. When steam erupted during the process, a proposal for geothermal power generation was made. In the spirit of sharing the region’s natural blessings, the project moved forward with a commitment to supply warm water to the local community. Building trust with local communities and stakeholders was essential, especially in a region dependent on tourism and agriculture.

Geographic and Geological Constraints

Remote and Mountainous Terrain

The plant’s location in the Hachimantai Plateau presented logistical difficulties. Transporting heavy equipment and materials to the site required the construction of access roads and infrastructure in rugged terrain. Seasonal weather conditions, including heavy snowfall, further complicated construction and maintenance efforts.

Volcanic Activity and Seismic Risk

Japan’s tectonic setting posed inherent risks to geothermal development. The region’s volcanic activity and seismic events necessitated robust structural design and contingency planning. Engineers had to ensure that wells, pipelines, and turbines could withstand seismic events without compromising safety or performance.

Unpredictable Subsurface Conditions

During early drilling at the Matsukawa site, the steam quality varied significantly among the wells. Some initial wells produced wet steam, which was not immediately suitable for optimal power generation. However, over time, the production stabilized, and the wells began to yield dry steam, enabling consistent plant operation. These geological uncertainties underscored the importance of adaptable plant design and reservoir management.

Legacy of Overcoming Challenges

The successful commissioning of the Matsukawa Geothermal Power Plant was a testament to Japan’s engineering ingenuity and collaborative spirit. By overcoming these multifaceted obstacles, the project laid the foundation for future geothermal development in Japan and Asia. It demonstrated that with careful planning, interdisciplinary cooperation, and adaptive problem-solving, renewable energy could thrive even in challenging environments. Today, Matsukawa stands not only as a functional power station but also as a symbol of resilience and innovation. Its continued operation for over five decades reflects the effectiveness of the solutions devised to address its early challenges—solutions that remain relevant to geothermal projects worldwide.

What features set this work apart from similar achievements?

Unique Features Compared to Global Predecessors

The Matsukawa Geothermal Power Plant, commissioned in 1966, holds a unique place in the global history of geothermal energy. While geothermal power had already been harnessed in countries such as Italy, the United States, and New Zealand, Matsukawa distinguished itself through its technological adaptations, environmental integration, and its role in shaping Japan’s renewable energy landscape. This section outlines the features that set Matsukawa apart from its international counterparts and highlights its pioneering contributions.

First Commercial Geothermal Plant in Japan and Asia

Matsukawa was the first commercial geothermal power plant in Japan and the broader Asian region, marking a significant milestone in the diversification of energy sources in a country heavily reliant on imported fossil fuels. Unlike Italy’s Larderello (1911) and the United States’ The Geysers (1960), which were situated in regions with long-standing geothermal traditions, Matsukawa represented a significant technological advancement in a region with no prior commercial geothermal development. Its success demonstrated the viability of geothermal energy in a new geological and regulatory context, paving the way for future developments across Asia.

Adaptation of Dry Steam Technology to Japan’s Volcanic Geology

At the Matsukawa plant, the adaptation of dry steam technology to volcanic geological conditions was a key technical milestone. Initial production wells sometimes yielded wet steam, but over a period of six months to a year, they transitioned to producing dry steam. This natural change in steam characteristics allowed effective implementation of dry steam systems. Unlike later geothermal plants, Matsukawa did not employ gas scrubbers or specialized drainage systems, relying instead on the inherent quality of the steam as it improved over time.

Integration with Environmental and Agricultural Systems

The warm water generated and supplied by the power plant after steam utilization was distributed to nearby agricultural operations, including greenhouses. This integration supported year-round farming and exemplified a model of energy-agriculture symbiosis. The use of this warm water contributed to both energy efficiency and sustainable regional development.

Community Engagement and Public Acceptance

Unlike its Western counterparts, Matsukawa’s development involved extensive community engagement. Drilling initially began for the purpose of developing hot spring resorts, but was later repurposed for geothermal power generation. This gradual approach helped build public trust and acceptance in a region where geothermal energy was unfamiliar. In contrast, plants like Wairakei in New Zealand faced early criticism over environmental impacts, including subsidence and changes to geyser activity.

Mechanical Engineering Heritage Recognition

In 2016, Matsukawa was designated a Mechanical Engineering Heritage site by the Japan Society of Mechanical Engineers. This recognition underscores its historical and technical significance, not only as a power generator but as a symbol of Japan’s engineering ingenuity. While Larderello and The Geysers are celebrated for their scale and longevity, Matsukawa is honored for its pioneering spirit and its role in establishing geothermal energy as a viable option in Japan’s energy mix.

Operational Longevity and Stability

Matsukawa has maintained stable operations for over five decades, a testament to its robust design and sustainable resource management. While The Geysers experienced fluctuations in output due to reservoir depletion and required reinjection strategies, Matsukawa’s conservative extraction and reservoir monitoring have ensured consistent performance. This operational stability is particularly notable given Japan’s seismic activity and the plant’s location in a mountainous region.

Educational and Demonstration Role

Matsukawa has served as a model and educational site for geothermal development in Japan. The establishment of the Matsukawa Geothermal Museum and its use in training engineers and policymakers has amplified its impact beyond electricity generation. In contrast, earlier plants were primarily industrial in focus, with limited public outreach or educational initiatives.

Strategic Importance Post-Fukushima

Following the 2011 Fukushima Daiichi nuclear disaster, Matsukawa gained renewed attention as a symbol of safe and renewable energy. Its long-standing operation and minimal environmental footprint positioned it as a credible alternative to nuclear power. This strategic relevance distinguishes it from older plants that were not developed with disaster resilience or public safety in mind.

Conclusion

While geothermal power had been successfully harnessed in Italy, the United States, and New Zealand prior to Matsukawa’s commissioning, the Japanese plant introduced a new paradigm in geothermal development. Its adaptation of dry steam technology to Japan’s unique geology, its integration with local ecosystems, and its emphasis on public engagement and long-term sustainability set it apart from its predecessors. Matsukawa’s legacy continues to inspire geothermal innovation across Asia and serves as a benchmark for responsible and resilient energy development.

Why was the achievement successful and impactful?

Success Factors and Impact of the Matsukawa Geothermal Power Plant

The Matsukawa Geothermal Power Plant, commissioned in 1966, stands as a landmark achievement in Japan’s energy history. Its success and impact stem from a combination of technical innovation, strategic foresight, environmental stewardship, and social engagement. As Japan’s first commercial geothermal power station, Matsukawa not only proved the viability of geothermal energy in a new regional context but also laid the foundation for future renewable energy development across Asia.

Technical Success Through Adaptation and Innovation

One of the early technical challenges at Matsukawa was the presence of fine rock dust in the steam, which caused erosion and deposition on turbine blades. These issues were addressed through improvements in blade materials and surface design. Over time, the steam transitioned from wet to dry, and operational stability improved. Unlike later geothermal systems, issues such as reservoir pressure instability or extensive turbine redesign were not significant concerns. The lessons learned at Matsukawa laid the groundwork for more resilient and efficient geothermal plant designs in Japan.

Strategic Timing and National Relevance

The plant’s commissioning coincided with Japan’s post-war industrial expansion and growing energy demands. At a time when the country was heavily reliant on imported fossil fuels, Matsukawa offered a domestic, renewable alternative. Its success demonstrated that geothermal energy could contribute meaningfully to Japan’s energy mix, influencing policy discussions and encouraging further exploration. In the wake of the 2011 Fukushima nuclear disaster, Matsukawa's proven track record of safe, clean, and decentralized energy production re-emerged as a compelling alternative to nuclear power, influencing Japan’s post-disaster energy strategy.

Environmental Integration and Resource Efficiency

The Matsukawa plant developed a system to supply warm water—generated from steam—to the local community, particularly for agricultural use. This approach not only utilized the thermal energy efficiently but also contributed to the sustainability of the surrounding region. The integration of energy production with community benefit stands as a model of environmental harmony and circular resource utilization.

Social Engagement and Educational Value

Matsukawa’s development involved close collaboration with local communities, fostering a mutually beneficial relationship. The establishment of the Matsukawa Geothermal Museum and its use as an educational site helped raise public awareness about geothermal energy. The plant became a model for community-integrated renewable projects, demonstrating that technical success must be accompanied by social acceptance to achieve lasting impact.

Recognition and Legacy

In 2016, Matsukawa was designated a Mechanical Engineering Heritage site by the Japan Society of Mechanical Engineers, affirming its historical and technical significance. Its continued operation and influence on geothermal policy and education underscore its enduring legacy. Matsukawa’s success is not merely measured in megawatts, but in its role as a catalyst for innovation, sustainability, and public trust in renewable energy.

Supporting texts and citations to establish the dates, location, and importance of the achievement: Minimum of five (5), but as many as needed to support the milestone, such as patents, contemporary newspaper articles, journal articles, or chapters in scholarly books. 'Scholarly' is defined as peer-reviewed, with references, and published. You must supply the texts or excerpts themselves, not just the references. At least one of the references must be from a scholarly book or journal article. All supporting materials must be in English, or accompanied by an English translation.

References

[1] Mitsuyuki Hanano, Koichi KOTANAKA, Takashi OYAMA: “Operation and Reservoir Management of the Matsukawa Geothermal Power Station”, Journal of the Geothermal Research Society of Japan, pp. 1-25, Vol. 26, No. 2 (ser. 107), 1989.

Abstract:

This paper reports operation and reservoir management of the Matsukawa geothermal power plant. This includes a summary of the production records of the power plant and well head data of all the wells, a review of the results of physical and chemical reservoir monitoring, and a discussion on current issues for stable operation of the power plant.

The Matsukawa geothermal power station has a vapor dominated geothermal reservoir which has been the only extensive one found in Japan. The first ever geothermal power generation in Japan was started in Matsukawa in October 1966 by Japan Metals & Chemicals Co., Ltd. Power generation at Matsukawa has been continued successfully for more than twenty-two years. The present output is 22 MW with 10 production wells. Cumulative electric energy produced, an average output and the utilization factor over twenty-two years are 3.53 x 106MWh, 19.6MW and 86 percent respectively,

Water level monitoring and pressure build-up test have been conducted as a physical reservoir monitoring. From the water level monitoring at a well T-22 which is located at the center of the production area, an approximate average of decrease of the reservoir pressure during the last few years was 0.2 bar per year, which is very small. From the most recent pressure build-up test, shut-in pressure there is higher in south-west of the production area and there is a steep pressure gradient from south-west to north-east. This suggests that there is a lateral steam flow from south-west to north-east in the reservoir and most of steam currently produced is supplied from south-west. M-7 which has the highest shut-in pressure and is one of the most south-western wells, produces the most steam and its rate of decrease over eighteen years is less than 1 t/h per year. These facts suggest that the Matsukawa geothermal reservoir still has enough potential to maintain its rated output, 22 MW.

From the chemical reservoir monitoring, steam produced at southwestern wells are richer chemically in old meteoric water, and poorer in younger meteoric water and volcanic gas compared with northwestern wells. It suggests that the chemistry of the steam Is controlled by local pressure balance.

Most of the steam currently produced at Matsukawa is dry superheated steam. Recently, the degree of superheat has become higher especially at north-eastern wells. Thus, re-injection of condensate is planned to support reservoir pressure and to maintain stable steam production.

A small-scale experiment has been conducted since March 1988, to assess its effect on steam production,

[2] Mineyuki HANANO: "Reservoir Engineering Studies at the Matsukawa Geothermal Field", Journal of the Geothermal Research Society of Japan, pp. 255-284, Vol. 16, No. 3 (1994)

Abstract:

Matsukawa was the first geothermal power plant established in Japan. It started power production in October 1966 and is the only vapor-dominated geothermal field developed to date. The power plant has been continuously producing full power, 22MWe, for almost 27 years. Matsukawa is located about 600km northeast of Tokyo and about 27km northwest of Morioka, Japan. It is in the Hachimantai volcanic region, one of the most active volcanic regions in Japan. This paper reviews reservoir engineering studies at Matsukawa. This includes a study of the current state of the reservoir studied mainly by pressure buildup tests, a study of the initial state of the reservoir studied mainly by reconstruction of a reservoir pressure profile, and a numerical modeling study of the natural state of the reservoir.

Continued pressure buildup tests since 1986 have revealed that there is a lateral steam flow from southwest to northeast in the Matsukawa vapor-dominated reservoir, and most of the steam is supplied from southwest of the development area. This result suggests that the vapor-dominated reservoir extends further southwest than the area now being exploited. These conclusions are supported by production records and chemical data of produced steam.

The study on the natural state of the Matsukawa geothermal reservoir has revealed that there was a thin vapor-dominated zone at the shallow part of the reservoir (around 300m to 400m depth) and the current production zone (800m to 1300m depth) was filled with liquid before exploitation.

Early production wells produced wet steam with some hot water at first, but they turned to produce only dry steam after a production period of 6 months to 1 year, because of the existence of low permeability aureole around the reservoir and high heat flow. Estimated conductive heat flux, 1.5W/m2 is as high as that of The Geysers.

The natural state modeling study showed that the model of the initial state of the reservoir, described above, was feasible. The results also indicated that the low permeability aureole was very important for the evolution of its natural state and also for production of superheated steam from the liquid zone below the thin vapor-dominated zone in the shallow part of the reservoir. Initial temperature distribution and the results of the simulation study suggest that there is an extensive heat source in the southwestern part of the reservoir.

[3] Tatsuya KAJIWARA, Mineyuki HANANO, Takemi OHMIYA, Koichi KOTANAKA: “The Efforts for Sustainable Steam Production and Electrical Power Generation in the Matsukawa Geothermal Field, Japan”, Journal of The Geothermal Research Society of Japan, Vo. 26, No. 2, pp. 135-145, 2004, DOI: 0.11367/grsj1979.26.135

Abstract:

This paper reports successful operation of the Matsukawa geothermal power plant since 1966. This includes a summary of the production and electrical power records of the power plant. The wells and reservoir have shown a very slow decline, which is a result of appropriate station sizing and adequate operational criteria. The power plant was sized only to meet the demand of the company's factory for its in-house electric use, instead of full utilization of the resource. The power plant has been operated so as to maximize the profit instead of insisting on operating continuously at full power. A proper understanding of the reservoir based on some chemical and physical monitoring data has helped to maintain stable operation. Station sizing (23.5 MWe since 1993) appears to be the most important factor in the successful development and operation of the Matsukawa geothermal field.

[4] Jun SATO: "Overview of the Matsukawa Geothermal Power Plant," Journal of the Institute of Electrical Engineers of Japan (IEEJ), pp. 45–56, Vol. 87-11, No. 950, 1967.

[Translation to English: Chapter 1]

1. Background of Matsukawa Geothermal Development

In 1952 (Showa 27), when Matsuo Village in Iwate Prefecture began drilling in the Matsukawa area to develop hot springs, instead of hot water, they encountered an unusual eruption of steam. This marked the beginning of what is now the Matsukawa Geothermal Power Plant. Recognizing the potential of geothermal energy, Toka Kogyo—an enterprise mainly engaged in electric furnace operations for the energy-intensive ferroalloy industry—initiated a site survey in 1956 (Showa 31).

Since then, the company began foundational survey research in collaboration with the Geological Survey of the Industrial Technology Agency. In 1963 (Showa 38), with approval from the Science and Technology Agency, full-scale development began under a partial contract with the New Technology Development Corporation.

Regarding the production wells, drilling of Well No. 1 commenced in August of the same year, and by January of the following year, it yielded more steam than expected. Wells No. 2 and 3 were subsequently developed in succession.

Initially, the plan was to generate 5,000 kW of electricity. However, due to the unexpectedly high steam output from Well No. 1, the plan was quickly revised to 20,000 kW. Equipment planning was carried out between 1964 and 1966 (Showa 39–41), followed by construction from 1965 to 1966 (Showa 40–41), and eventually, test operations began in September 1966, with commercial operations starting in October of the same year.

[5] Mineyuki HANANO: “Success of the First Commercial Scale Geothermal Power Development in Japan; Matsukawa Geothermal Power Station”, Journal of the Mining and Materials Processing Institute of Japan (MMIJ), pp. 214-222, Vol. 33, No. 9, 2017.

Abstract:

The Matsukawa geothermal power station has been in commercial operation since 1966. its geothermal reservoir was discovered by chance, by drilling of hot spring wells by the local administration in 1952, Japan Metals & Chemicals (JMC) noticed this phenomenon and started exploitation for a geothermal power development in 1956. Then, JMC and Geological Survey of Japan (GSJ) started collaborative study in 1958.

The biggest technical challenge for success in Matsukawa was a decision of drilling target depth for steam production and a casing shoe depth to stop in-Row of shallow cold water. It was examined through measurements of water levels in three exploration wells, borehole temperature profiles and flow rates of rivers. Geological and geophysical studies by GSJ helped this study. Owing to this study, the Ist production well succeeded to produce dry steam in 1964 and ted to a success in the first commercial scale geothermal power development in Japan.

[6] Hisayoshi NAKAMURA: “Geothermal Exploration and Subsurfaee Structure of Matsukawa Area, Northeast Japan”, SPECIAL ISSUE, MATSUKAWA GEOTHERMAL DEVELOPMENT, JAPAN GEOTHERMAL ENERGY ASSOCIATION, pp. 13-34, No. 10, MAY. 1967

Abstract:

In Matsukawa geothermal area, about 50 km far from Morioka to north, seven bore holes were made to get thermal water for bathing by Matsuo village office during 1952~1955. This was the beginning of geothermal exploration in this area. By the drilling, it became clear that this area has a cap rock called Matsukawa andesite in the uppermost part and geothermal steam emitted from dacite tuff and its lava (Tamagawa welded tuff) overlain by Matsukawa andesite in the depth of 200---300m, though geothermal manifestations are poor on the surface. Geologic columns of the bore holes are shown in Fig. 3.

From 1957 to 1961, regular exploration was made under the cooperation of Geological Survey of Japan and Azuma Kako Co. Ltd. Geological survey and geophysical prospecting by seismic, electric and logging methods were made by the former and drilling was carried out by the latter.

The result obtained from the geothermal investigations in this period is summarized in Fig. 7.

To get geothermal steam reserved in Tertary welded tuff and Yamatsuda formation (Figs. 8 and 9), four productive wells have been drilled by Azuma Kako Co. by subsidy of the Japanese Govermemt since 1963.

The depths of MR-1~MR-4 wells the locations of which are shown in Fig. 10, are 945, 1080, 1200 and 1500 in respectively. The position of each well was determined by using and discussing the data obtained from the above-mentioned geothermal investigations.

According to the core investigation of each productive well, the stratigraphic profile and stratigraphic sequence are shown in Figs. 11 and 12.

Figs 13 and 14 are the distribution map of altered rocks. As seen in Table 2, the altered rocks of this area are classified into weakly altered zone, montmorillonite zone, kaolin zone, alunite zone and pyrophyllite zone. Except pyrophyllite zone, zonal arrangement of altered rocks can be seen in horizontal and vertical distributions. From the chemical composition of drainage water of each well (Table 4), it was clarified that alunite and kaolin have been formed under the acidic condition. While, the temperature near surface of this area is not so high as pyrophyllite can be formed, and therefore, it is assumed that pyrophyllite would not be the same product as other minerals, but that of early stage of geothermal activity.

From the data of stratigraphic profile in each well (Fig. 11), structural contour map presented by the depth to the top of Yamatsuda formation is made as shown in Figs. 16 and 17. If the bedding planes of the basement rocks are nearly horizontal as seen in core samples of welded tuff, this means -that there may be fault zone pararell to structural contour lines, namely along Matsukawa river, and then it may be assumed that the structural movement would be associated with the activity of Marumori volcano (Fig. 17).

When drilling was being made, leakages of mud water from bare holes occurred often in welded tuff formation and especially in Yamatsuda formatio. From this fact, it can be said that Yamatsuda formation plays the principal role as reservoir in this area. Fig. 15 shows that leakages of mud water occurred in the hard rocks of the welded tuff formation having horizontal welding planes.

Summarizing the data obtained from drifting, the schematic profile of subsurface structure and occurrence of geothermal resource in the Matsukawa area are shown in Fig. 18.

MR-1, MR-2 and MR-3 wells have succeeded to get geothermal steam of 150 tons per hour in total discharge. Japan's first geothermal power plant was put. in operation, October, 1966. Its capacity is 15000 kilowatts at present.

[7] Masami HAYAKAWA: “Geophysical Study at Matsukawa Geothermal Area”, SPECIAL ISSUE, MATSUKAWA GEOTHERMAL DEVELOPMENT, JAPAN GEOTHERMAL ENERGY ASSOCIATION, pp. 35-51, No. 10, MAY. 1967

Abstract:

Before explaining on Geophysical Study at Matsukawa Geothermal area, the writer tried to summarize the role of geophysical prospecting to make clear the underground structure of geothermal field.

At the present stage, it is difficult to know the true picture of geothermal structure including the hydrothermal system and the behavior of magma by only one geophysical method, that means the synthesized method of various kinds of geophysical prospecting and also geological and geochemical studies will be most elective for our present purpose.

Besides this, new techniques are very necessary to establish the Reservoir engineering as in the case of oil prospecting.

The writer will explain on the geophysical study at Matsukawa a little in detail in the following. For this study, many of my friend have joined. They are Messrs. K. Baba, S. Takaki, S. Tanaka, K. Mori, Y. Ono (Geological Survey of Japan), Members of Azumakako Co., Members of Teikoku Oil Co. And also, Prof. H. Takeuchi of the University of Tokyo helped me in considering the heat problem. The writer wishes to express his cordial thanks to them.

During last eight years since 1958, the writers have conducted seismic and electrical prospecting and geophysical logging by using some test wells. Besides these, Hayakawa has also calculated the underground temperature distribution under the assumption of some geophysical states, paralleling to the geological studies described in the previous paper, they started with laboratory experiments including density, porosity, and ultrasonic wave velocity measurements by using the specimens of outcrops at and adjacent area of this geothermal field.

From these results tentatively they presumed as follows by combining geological data. Matsukawa andesite might correspond to the first cover-rock because of the high velocity and low porosity while the subsequent dacite tuff formation probably- might be the first reservoir of hot water because of low velocity and high porosity. Likewise, the dacite lava beneath the dacite tuff might correspond to the second cover-rock and the underlaid marine sediments correspond to the second reservoir.

Consequently, they rather preferred the reflection seismic method instead of refraction method because the seismic velocity might not increase with depth. For the seismic prospecting we utilized the magnetic tape-recording system and after the several trials of playback, some nice reflection records were obtained. (Fig. 8)

The vertical axis shows the depth from the surface in meter and the horizontal axis shows the lateral distances between shat to detectors.

As the result of seismic records depths of reflection interfaces from the surface were obtained, and they are 160, 550, 980. 1300, and 2000 meters. By taking the geological events into consideration, these reflection faces should correspond to the boundaries between different formations. As explained before, the first layer consisting of hard andesite may be the cover-rock. Below this from 160 meters to 550 in depth. there is possible reservoir for hot water.

The layer between 550 and 980 meters corresponds to the dacite formation and as already explained before this formation was named the second cover-rock. But this is not so complete cover-rock as the first on6, as it includes some cracks according to the seismograms. Below this layer to 1300 meters, there ' will be sedimentary formation, below this to 2000 meters, there will be so-called Green-tuff formation. From seismic records it is easy to predict vertical fissures in it, which will provide steam and gas paths. than 2000 meters the material must correspond to chert or slate of Paleozoic formation.

Some test bore-holes were drilled from which we. could obtain the temperature distribution in the shallow part ih this area. It was very elective for us to know the temperature distribution in the shallow part of this field. This result did not contradict with the presumed fault structure in seismic profile.

Also, the result of the~ temperature calculation ~ did not contradict with the present shallow temperature curves, paralleling with seismic prospecting, electrical prospecting was also conducted. In the case of seismic survey, the traverse line was set along Matsukawa River. In the electrical prospecting the traverse lines were set not only in the same direction of seismic one but also in the perpendicular direction of it. They applied vertical electric sounding of Schlumberger method. The maximum distance between two current electrodes was 4 kilo-meters and many resistivity data were obtained, (Fig. 9). Generally speaking, all of such curve show more or less the same character. In the abscissa you will see the half of electrode distance that is AB/2 in meter. In the ordinate you - will see the apparent resistivity in ohm-meter. Both of them are expressed in logarithmic scale.

Aa you see here, the electric apparent resistivity shows higher in the shallow part and it shows low resistivity in the intermediate. Again, there is resistivity high, By the calculation the first high is thought to correspond to the surface debris or the first cover as in the seismic prospecting, first low to the first reservoir and the second high may correspond to the second cover. In some of the curves we can see the second low resistivity at deeper part. Probably this may indicate the existence of the marine sediments.

Here is a resistivity profile with some of resistivity logging data which correspond to the perpendicular direction to the seismic traverse. (Fig. 10) As is in the case of seismic profile the vertical line shows the depth from the surface, and the scale of both horizontal and vertical direction is the same each other. As will be seen easily from this profile, near the surface there are debris or the first cover> below this the first reservoir and finally the second cover. This, the second cover part has comparatively high resistivity as shown here, 100 ~ 2000Ωm. It means that this formation does not contain clayey material and is more compact formation than overlain formation. As the writer will write later, however, we have found that this part can feed a lot of steam and hot water through the wells at present productive area.

Although soon later the writer will explain about electrical logging, tentatively yon will see the resistivity logs here in this profile. As you will see easily here the high resistivity part in this profile just corresponds to the high resistivity logging data. If we look carefully at this high resistive part of log, we can see the minute low resistivity values among the high resistivity domain in the log which may indicate the existence of fissures in the compact lava.

You will see the electric logs in Fig. 11. The vertical line indicates the depth from the surface in meter. On the right side of the axis the resistivity values are shown in ohm-meter while on the left side self-potentials are shown in milli-volt. These dotted lines are the boundaries between Matsukawa andesite and dacite tuff, and dacite lava and marine sediments respectively obtained by' geological core analysis. In between these two dotted lines you will see the break-lines which connect each other the similar characteristic part of each curve.

Now let's here remember some experiments in test ' wells. By using the data obtained from these test wells we can say the surface cold water might Bow seasonally into the so-called first reservoir. On the other hand, the resistivity logs show small value in shallow part, say about until 550 meters while at deeper part than that depth resistivity value shows high especially in well No. L So synthesizing the above phenomena, we decided to set the casing pipe until the depth of 550 meters to avoid the surface cold water flow into the well Later this arrangement was proved to be good. Anyway, in the deeper part than this depth we set slotted pipes.

Now you will see the temperature recovery curves by taking example of veil No. 1. in Fig. 13.

In vertical line the depth from the surface is shown in meter as in the former case and in the horizontal line, temperature is shown in degree-centigrade. Immediately after the completion of the well, the mud water which was used for drilling was replaced by the pure cold water. One day after this arrangement the temperature curve became like the figure. The second day, the temperature increased a little. Likewise, finally one week later the temperature became higher as in the Egure.

From Hayakawa's calculation of underground temperature distribution, we expected the temperature of 300℃ at the depth of 1000 meters, so we expected as if the temperature might increase a little more than the final curves in this graph, however* we could not help stopping measurement at this stage because of some financial reason. Consequently, some amount of water was taken out from the well and suddenly a lot of steam were gushing out from the outlet of this well with the amount of 60 tons per hour under about 6 kg/cm2 pressure which might correspond to 6,000kW from this only one well.

Likewise, another three wells began to discharge steam and water also immediately after excluding some amount of water from the well head. Fig. 12. shows the results of the final temperature measurement conducted just before making them ta discharge steam' and hot water.

Now let's go back to the temperature recovery curves of No. 1 well showed before in Fig. 13, and pay our notice to these comparatively high temperature parts which showed the rapid temperature increase in the later stage of this one week. By comparing these parts with the resistivity logs we can say that hot water or steam was penetrating from the country formation into the well through fissures.

Finally, by taking these facts we have arrived at the following conclusion regarding the existing state of hot water or steam.

At the beginning stage of the study, we thought that the 'second cover rock formation could not supply a lot of steam and hot water for the well which penetrated it. But finally, it became clear from many evidences just the writer told that hot water or consequently steam might come from the deep heat source t6rough the faults, fissures or cracks into the narrow pockets in the lava of so-called second cover. The rocks which form the first reservoir are more porous than the second cover-rock, of courses, but that reservoir does not contain hot water and steam enough to supply for the productive wells because it does not possess many cracks and fissures, and furthermore the surface cold water may Bow into it as I told before.

Consequently, we are now tapping the hot water and steam from the hard formation named firstly as the second cover and from the second reservoir. because the hard formation has plenty of cracks and-or fissures, and it also acts as the cover-rock against the surface cold water.

[8] Yoshitaro MORI: “Issues concerning Development of Matsukawa Geothermal Area”, SPECIAL ISSUE, MATSUKAWA GEOTHERMAL DEVELOPMENT, JAPAN GEOTHERMAL ENERGY ASSOCIATION, pp. 52-64, No. 10, MAY. 1967

Abstract:

On the eighth of October, 1966, a geothermal generating station, the very first one of this type in Japan, started in a business operation at Matsukawa after the elapse of just 10 years that followed the commencement of the initial stage of work of investigating feasibility of development of geothermal power potential in Japan. During this 10-year period, intensive efforts were directed toward the technological investigation in the engineering field never explored previously for drawing up the plan for the initial stage of development and for the design of various installations at the steam well It was due- to sheer luck that almost all of the aims of such efforts were achieved without hitch, not to mention the intensive co-operation on the parts of outside bodies.

At the completion of the general survey of the initial stage of work mentioned above, there was felt necessity of drawing up a development plan to pave the way for future industrialization of the enterprise of geothermal power generation. To do so, a series of lest drillings to progressive depths was caned for before starting in drilling the steam-producing well, for there was observed on the ground surface none of the conspicuous indication pinpointing where to drill in search of such underground steam. Accordingly, physical prospecting, geological surveys, chemical explorations, test borings and other general investigations of meteorological and riparian phenomena were conducted at respective phases of the work periods of basic survey and applied survey. On completion of these tests and surveys, the policy for the next stage of proceedings was adopted in accordance with the synthetic conclusion on the resulting findings, and drilling of a steam well more than 1000-meter deep was finally decided to be commenced. This adoption of said policy is thought to constitute the principal cause of enabling completion of the large steam well in the scale of the world level in its productive capacity.

As to the test of the characteristics of a steam well, there are several points calling tor intensive studies. The full shut-in pressure of the well is considered as one of such factors that affect the economic evaluation of the steam well and the design of the steam-electric generating equipment, and the advisability of carrying out such pressure test has been hotly discussed on several occasions. In consideration of the possible breakdown of the casing pipe and of the changes in the well characteristics due to the result of depositing the sediments in and around the steam bore hole, all the changes being attributable to the excessive steam pressure rise, such pressure test has never been put into practice so far. Various types of calorimeters and

dryness meters have been employed for measuring the wetness of the natural steam, but each has been found to have its own merits as well as demerits if to be employed as on-site devices for the purpose. Because of it, difficulties have been felt in obtaining reliable data sa far. Besides, there are still other issues calling for immediate attention such as the noise of emitting steam and its silencer and the pulsation of steam jets accompanying water at high temperature.

According to the experience obtained during the period of five months since the commencement of operation of the generating station, none of phenomenon of corrosion has been observed. However, the deposition of scale and the muddy sand grains accompanying the water emitted from the steam well are observed to be demanding more attention than expected before for the maintenance and operation of the generating plant in a good order.

Lastly, there is the issue of public nuisance, as one common among tile geothermal power projects, that demands for preventive measures. At this Matsukawa generating station* its silencer equipped for suppressing excessive steam jet noise has been found insufficient for the purpose. Various measures have also been employed to protect the vegetation from being damaged by what has been emitted by the steam well immediately after the emission of the steam. The disposal of the hot water released from the generating plant constitutes another issue, but such water is now being discharged into a river, as the prolonged experiences has proved that the hot water when disposed of in this manner is harmless to any of agricultural products. As to the contents of exhaust gas in the atmosphere around the generating station, no difference has been detected between those before and after the commencement of operation of the station, although detection of the gas contents has been put Into a routine practice.

Varieties of actual results of operation have so far been achieved to our satisfaction, yet there are a number of issues awaiting our immediate resolution, and for which resolution we shall have to concentrate all our efforts from now on.

Supporting materials (supported formats: GIF, JPEG, PNG, PDF, DOC): All supporting materials must be in English, or if not in English, accompanied by an English translation. You must supply the texts or excerpts themselves, not just the references. For documents that are copyright-encumbered, or which you do not have rights to post, email the documents themselves to ieee-history@ieee.org. Please see the Milestone Program Guidelines for more information. Please email a jpeg or PDF a letter in English, or with English translation, from the site owner(s) giving permission to place IEEE milestone plaque on the property, and a letter (or forwarded email) from the appropriate Section Chair supporting the Milestone application to ieee-history@ieee.org with the subject line "Attention: Milestone Administrator." Note that there are multiple texts of the letter depending on whether an IEEE organizational unit other than the section will be paying for the plaque(s). Please recommend reviewers by emailing their names and email addresses to ieee-history@ieee.org. Please include the docket number and brief title of your proposal in the subject line of all emails.