Milestone-Proposal:Invention of Temparature- Insensitive Quartz Oscillation Plate Enabling HIghly Stable Communications and Clocks, 1933

To see comments, or add a comment to this discussion, click here.

Docket #:2015-15

This Proposal has been approved, and is now a Milestone

To the proposer’s knowledge, is this achievement subject to litigation? No

Is the achievement you are proposing more than 25 years old? Yes

Is the achievement you are proposing within IEEE’s designated fields as defined by IEEE Bylaw I-104.11, namely: Engineering, Computer Sciences and Information Technology, Physical Sciences, Biological and Medical Sciences, Mathematics, Technical Communications, Education, Management, and Law and Policy. Yes

Did the achievement provide a meaningful benefit for humanity? Yes

Was it of at least regional importance? Yes

Has an IEEE Organizational Unit agreed to pay for the milestone plaque(s)? Yes

Has the IEEE Section(s) in which the plaque(s) will be located agreed to arrange the dedication ceremony? Yes

Has the IEEE Section in which the milestone is located agreed to take responsibility for the plaque after it is dedicated? Yes

Has the owner of the site agreed to have it designated as an IEEE Milestone? Yes

Year or range of years in which the achievement occurred:

1933

Title of the proposed milestone:

Invention of a Temperature-Insensitive Quartz Oscillation Plate, 1933

Plaque citation summarizing the achievement and its significance; if personal name(s) are included, such name(s) must follow the achievement itself in the citation wording: Text absolutely limited by plaque dimensions to 70 words; 60 is preferable for aesthetic reasons.

In April 1933, Issac Koga of the Tokyo Institute of Technology reported cutting angles that produced quartz crystal plates having a zero temperature coefficient of frequency. These angles, 54⁰ 45’ and 137⁰ 59’, he named the R1 and R2 cuts. Temperature-insensitive quartz crystal was used at first for radio transmitters and later for clocks, and has proven indispensable to all radio communication systems and much of information electronics.

200-250 word abstract describing the significance of the technical achievement being proposed, the person(s) involved, historical context, humanitarian and social impact, as well as any possible controversies the advocate might need to review.

IEEE technical societies and technical councils within whose fields of interest the Milestone proposal resides.

In what IEEE section(s) does it reside?

IEEE Tokyo Section

IEEE Organizational Unit(s) which have agreed to sponsor the Milestone:

IEEE Organizational Unit(s) paying for milestone plaque(s):

Unit: IEEE Tokyo Section

Senior Officer Name: Hiroki Fujishiro, IEEE Tokyo Section Teasurer

IEEE Organizational Unit(s) arranging the dedication ceremony:

Unit: IEEE Tokyo Section

Senior Officer Name: Hidenobu Harasaki, IEEE Tokyo Section Secretary

IEEE section(s) monitoring the plaque(s):

IEEE Section: IEEE Tokyo Section

IEEE Section Chair name: Kazuo Hagimoto, IEEE Tokyo Section Chair

Milestone proposer(s):

Proposer name: Kenichi IGA

Proposer email: Proposer's email masked to public

Proposer name: Taiji Nishizawa

Proposer email: Proposer's email masked to public

Please note: your email address and contact information will be masked on the website for privacy reasons. Only IEEE History Center Staff will be able to view the email address.

Street address(es) and GPS coordinates in decimal form of the intended milestone plaque site(s):

2–12–1, O-okayama, Meguro-ku, Tokyo, 152-8550 Japan

Describe briefly the intended site(s) of the milestone plaque(s). The intended site(s) must have a direct connection with the achievement (e.g. where developed, invented, tested, demonstrated, installed, or operated, etc.). A museum where a device or example of the technology is displayed, or the university where the inventor studied, are not, in themselves, sufficient connection for a milestone plaque.

Please give the details of the mounting, i.e. on the outside of the building, in the ground floor entrance hall, on a plinth on the grounds, etc. If visitors to the plaque site will need to go through security, or make an appointment, please give the contact information visitors will need.

Are the original buildings extant?

Yes, the Main Building of the Institute. (See photograph in Fig. 12)

Details of the plaque mounting:

In a special showcase at the Exhibition Room of the Institute Museum

How is the site protected/secured, and in what ways is it accessible to the public?

The Museum is open to the public on weekdays from 10:30 to 16:30. (Closed nights and holidays.)

Who is the present owner of the site(s)?

Tokyo Institute of Technology National University Corporation

What is the historical significance of the work (its technological, scientific, or social importance)? If personal names are included in citation, include detailed support at the end of this section preceded by "Justification for Inclusion of Name(s)". (see section 6 of Milestone Guidelines)

What obstacles (technical, political, geographic) needed to be overcome?

What features set this work apart from similar achievements?

In 1932, when Koga established his precise theoretical analysis of thickness vibration of anisotropic quartz crystal, no similar theory existed. Therefore, Koga's theory [2 and 3] was readily adopted in the field together with the practice of rotating the cutting angle around the crystallographic axis. This contributed worldwide to the application of zero-temperature-coefficient quartz plates.</dev>,br />

In late 1929 and early 1930, several proposals appeared for realization of zero-temperature-coefficient plates. Among them, a ring-type plate was considered promising, however it was unusable in actual transmitters owing to delicate design constraints.

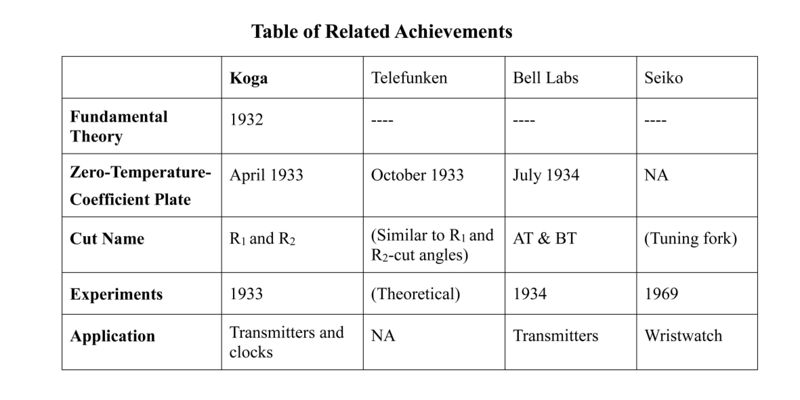

As explained, Koga concentrated on producing a zero-temperature-coefficient plate by rotating the cutting angle along the X-axis and realized an actual plate having a zero-coefficient in 1933 [7]. Similar work was being done in Europe and US, and this may be summarized as follows:Although Koga proposed tuning-fork vibration components in his studies before hitting upon a strict zero-temperature-coefficient vibrator R1-cut, the significance of the present Milestone Proposal differs greatly from that awarded Seiko. Therefore, the wristwatch Milestone in no way detracts from the originality of the present Issac Koga proposal.

Why was the achievement successful and impactful?

Supporting texts and citations to establish the dates, location, and importance of the achievement: Minimum of five (5), but as many as needed to support the milestone, such as patents, contemporary newspaper articles, journal articles, or chapters in scholarly books. 'Scholarly' is defined as peer-reviewed, with references, and published. You must supply the texts or excerpts themselves, not just the references. At least one of the references must be from a scholarly book or journal article. All supporting materials must be in English, or accompanied by an English translation.

In the references listed below, Koga's affiliated university name “Tokyo University of Engineering” refers to the older English appellation of the present-day “Tokyo Institute of Technology”.

Supporting materials (supported formats: GIF, JPEG, PNG, PDF, DOC): All supporting materials must be in English, or if not in English, accompanied by an English translation. You must supply the texts or excerpts themselves, not just the references. For documents that are copyright-encumbered, or which you do not have rights to post, email the documents themselves to ieee-history@ieee.org. Please see the Milestone Program Guidelines for more information.

Media:Koga's_biography.pdf

Media:Reference_1_Quartz_R1-cut_translated.pdf

Media:Reference_2_Quartz_R1-cut.pdf

Media:Reference_3_Quartz_R1-cut.pdf

Media:Reference_4_Quartz_R1-cut_translated.pdf

Media:Reference_5_Quartz_R1-cut_translated.pdf

Media:Reference_6_Quartz_R1-cut_translated.pdf

Media:Reference_7_Quartz_R1-cut_translated.pdf

Media:Reference_8_Quartz_R1-cut_translated.pdf

Media:Reference_9_Quartz_R1-cut.pdf

Media:Reference_10_Quartz_R1-cut_translated.pdf

Media:Reference_11_Quartz_R1-cut_translated.pdf

Media:Reference_12_Quartz_R1-cut.pdf

Media:Reference_1_Quartz_R1-cut_Japanese.pdf

Media:Reference_4_Quartz_R1-cut_Japanese.pdf

Media:Reference_5_Quartz_R1-cut_Japanese.pdf

Media:Reference_6_Quartz_R1-cut_Japanese.pdf

Media:Reference_7_Quartz_R1-cut_Japanese.pdf

Media:Reference_8_Quartz_R1-cut_Japanese.pdf

Media:Reference_10_Quartz_R1-cut_Japanese.pdf

Media:Reference_11_Quartz_R1-cut_Japanese.pdf

Please email a jpeg or PDF a letter in English, or with English translation, from the site owner(s) giving permission to place IEEE milestone plaque on the property, and a letter (or forwarded email) from the appropriate Section Chair supporting the Milestone application to ieee-history@ieee.org with the subject line "Attention: Milestone Administrator." Note that there are multiple texts of the letter depending on whether an IEEE organizational unit other than the section will be paying for the plaque(s).

Please recommend reviewers by emailing their names and email addresses to ieee-history@ieee.org. Please include the docket number and brief title of your proposal in the subject line of all emails.