Milestone-Proposal:The Engineering Data Analysis System sNOVA, 1989-1997

To see comments, or add a comment to this discussion, click here.

Docket #:2023-16

This proposal has been submitted for review.

To the proposer’s knowledge, is this achievement subject to litigation? No

Is the achievement you are proposing more than 25 years old? Yes

Is the achievement you are proposing within IEEE’s designated fields as defined by IEEE Bylaw I-104.11, namely: Engineering, Computer Sciences and Information Technology, Physical Sciences, Biological and Medical Sciences, Mathematics, Technical Communications, Education, Management, and Law and Policy. Yes

Did the achievement provide a meaningful benefit for humanity? Yes

Was it of at least regional importance? Yes

Has an IEEE Organizational Unit agreed to pay for the milestone plaque(s)? Yes

Has the IEEE Section(s) in which the plaque(s) will be located agreed to arrange the dedication ceremony? Yes

Has the IEEE Section in which the milestone is located agreed to take responsibility for the plaque after it is dedicated? Yes

Has the owner of the site agreed to have it designated as an IEEE Milestone? Yes

Year or range of years in which the achievement occurred:

1989-2008

Title of the proposed milestone:

The Engineering Data Analysis System sNOVA, 1989-2008

Plaque citation summarizing the achievement and its significance; if personal name(s) are included, such name(s) must follow the achievement itself in the citation wording: Text absolutely limited by plaque dimensions to 70 words; 60 is preferable for aesthetic reasons.

sNOVA, an industrial optimization platform originating from Macronix, transformed the automation of the entire semiconductor industry chain, establishing Taiwan as a global semiconductor production base. With remarkable features such as shortening production debugging time for abnormalities, reducing wafer-layer costs, improving product quality, and automatically adjusting the precision of production machine process parameters, sNOVA pioneered the digital transformation of semiconductor manufacturing through artificial intelligence and big data technology.

Chinese version

源於旺宏的一個產業優化平台sNOVA,牽動著整個半導體產業鏈的自動化,也讓台灣成為全球半導體生產大本營。 sNOVA以縮短生產異常調試時間、降低晶圓層成本、提升產品質量、自動調整生產機器工藝參數精度等顯著特點,開創了半導體製造通過人工智能和大數據技術實現數位轉型的先河。

200-250 word abstract describing the significance of the technical achievement being proposed, the person(s) involved, historical context, humanitarian and social impact, as well as any possible controversies the advocate might need to review.

sNOVA, nicknamed “Super Nova”, is an electronics data analysis system developed by Macronix, a company established in Taiwan in the 1980s and is the world’s leading manufacturer of non-volatile memory ROM and NOR Flash. Given the hundreds to thousands of processes in complex semiconductor manufacturing, it can take weeks to identify error sources and fix them under abnormal circumstances. The sNOVA system can detect problems causing abnormal quality or low yield within minutes. Meaningful fault management is achieved through long-term analysis of vast amounts of process parameter combinations in semiconductor manufacturing. This innovative system, which originated at Macronix as early as 35 years ago, has been adopted and embedded in many other semiconductor fabs, such as TSMC and UMC, paving the way for Taiwan to play a key role in global chip manufacturing.

The sNOVA concept was rooted in efforts to rival Japanese companies in semiconductor manufacturing. In the 1980s, Japan had a dominant share in the global semiconductor market due to its rigorous work ethic and high-quality standards. To compete with the highly disciplined Japanese, Macronix not only implemented the "5S3U" work code to improve employee discipline but also introduced statistical methods into the production process and took lead in the world to establish the sNOVA system. The production lines have been fully computerized since its establishment, and all production parameters are computer-controlled to reduce the influence of operators. As data accumulates rapidly during manufacturing, statistics experts developed sNOVA using data mining techniques to enhance manufacturing efficiency and improve quality. Bridging the gap between statistics experts and semiconductor engineers enabled data-driven management, ensuring the highest quality products and maximum productivity.

sNOVA was initially developed using IBM technology and the statistical software RS1, so it could only use basic statistical tests and SPC. However, statistical tests could already be used to replace engineers' judgment on process issues. In the later stages of sNOVA's development (2004~2008), in addition to using JAVA to develop the system in-house, SPSS and Matlab statistical software were also used to improve the quality of semiconductor manufacturing further and reduce human decision-making through DOE, Regression, Reliability Analysis, Cluster Analysis, Principle Component Analysis, Factor-analysis, Time Series, State-Space Model and other methods for Auto. Recipe Tuning, Fault Detection, Virtual Metrology, and Abnormal Wafer Map Detection. After 2008, the sNOVA system continues to apply more technologies such as Decision Trees, Neural Networks, Heuristic Algorithms, Deep Learning algorithms, etc. in production scheduling optimization and image recognition.

The development of sNOVA enabled Macronix to take the lead in semiconductor manufacturing. Macronix became the first memory company in the world to measure product defect rates in parts per billion (PPB) instead of parts per million (PPM), setting a new global standard for quality in the semiconductor industry. sNOVA innovative system has been adopted and embedded in many other semiconductor fabs, such as TSMC and UMC, paving the way for Taiwan to play a key role in global chip manufacturing.

IEEE technical societies and technical councils within whose fields of interest the Milestone proposal resides.

Electron Devices Society

In what IEEE section(s) does it reside?

IEEE Taipei Section

IEEE Organizational Unit(s) which have agreed to sponsor the Milestone:

IEEE Organizational Unit(s) paying for milestone plaque(s):

Unit: IEEE Taipei Section

Senior Officer Name: Pei-Wen Li

IEEE Organizational Unit(s) arranging the dedication ceremony:

Unit: IEEE Taipei Section

Senior Officer Name: Pei-Wen Li

IEEE section(s) monitoring the plaque(s):

IEEE Section: IEEE Taipei Section

IEEE Section Chair name: Pei-Wen Li

Milestone proposer(s):

Proposer name: Ruey-Beei Wu

Proposer email: Proposer's email masked to public

Please note: your email address and contact information will be masked on the website for privacy reasons. Only IEEE History Center Staff will be able to view the email address.

Street address(es) and GPS coordinates in decimal form of the intended milestone plaque site(s):

No. 16, Lixing Rd., East Dist., Hsinchu City , Taiwan (R.O.C.) GPS coordinates: x 24.80361 y 120.96861

Describe briefly the intended site(s) of the milestone plaque(s). The intended site(s) must have a direct connection with the achievement (e.g. where developed, invented, tested, demonstrated, installed, or operated, etc.). A museum where a device or example of the technology is displayed, or the university where the inventor studied, are not, in themselves, sufficient connection for a milestone plaque.

Please give the details of the mounting, i.e. on the outside of the building, in the ground floor entrance hall, on a plinth on the grounds, etc. If visitors to the plaque site will need to go through security, or make an appointment, please give the contact information visitors will need.

The intended site for this plaque is the exhibition hall located on the first floor of the Macronix headquarters. This location is the nearest publicly accessible building to the area where sNOVA was originally developed.

Are the original buildings extant?

Yes

Details of the plaque mounting:

The intended location for the plaque is an exhibition hall on the first floor of the Macronix headquarters. A picture providing an overview of the hall is included below for reference.

How is the site protected/secured, and in what ways is it accessible to the public?

The building is open on weekdays. The site is protected/secured by a security company and security cameras.

Who is the present owner of the site(s)?

Macronix

What is the historical significance of the work (its technological, scientific, or social importance)? If personal names are included in citation, include detailed support at the end of this section preceded by "Justification for Inclusion of Name(s)". (see section 6 of Milestone Guidelines)

sNOVA leads global semiconductor manufacturing into the era of AI and Big Data

In 1989, Macronix took the lead in Taiwan and the world to employ statistics experts in semiconductor fabs. Combining statistics and semiconductor knowledge, Cheng-yung PENG (彭誠湧), a Statistical Process Control (SPC) engineer and head of the in-house SPC system project, led the team to develop the prototype of the engineering data analysis system sNOVA, which can quickly identify issues causing quality abnormalities or low yield, ensuring top-quality products and services for customers.

As a pioneering system in Taiwan, sNOVA not only ushered in the era of AI and Big Data in global semiconductor manufacturing but also established Macronix as the world's first paperless fab from its inception.

The implementation of sNOVA inspired other high-tech companies in Taiwan to adopt similar practices, leveraging its know-how to develop their own systems and enhance product quality. For instance, Taiwan’s United Microelectronics Corp. (UMC) and Taiwan Semiconductor Manufacturing Co., Ltd. (TSMC), which now holds the highest market share in global wafer production, both implemented computerized systems following Macronix's example. These systems not only improved in-house management efficiency but also streamlined the integration of production lines.

This groundbreaking innovation set the foundation for Taiwan’s prominent role in global chip manufacturing. C.C. Wei, president of TSMC, commended Macronix’s mindset and practices as “very innovative.” [1]

The system has effectively improved the product defect rate from PPM to PPB

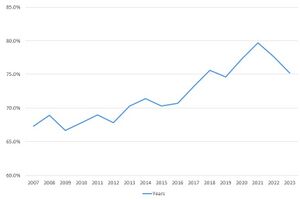

In the past, engineers at Macronix and in the semiconductor industry often had to spend more than a week identifying the root cause of errors across hundreds of complex semiconductor manufacturing processes. However, with sNOVA, engineers can now pinpoint problems within just a few minutes. The sNOVA system has significantly improved the product quality yield rate to better than 500 PPB (defect rate per billion is less than 500). Macronix has also become the world’s first memory company to measure product defect rates in parts per billion (PPB) rather than parts per million (PPM) (Fig. 1).

Because every production process is introduced into the sNOVA system, the quality of Macronix’s products has been continuously enhanced. High product quality enabled Macronix to supply the aerospace industry, which is one of the most demanding environments. Macronix cooperated with Xilinx in 2015 to launch the industry's first commercial flash memory product with an extreme temperature range of -55°C to +125°C, designed to meet the stringent reliability requirements of the aerospace and defense market. [2]

In the radiation resistance test of the product, the European Space Agency (ESA) and Alter Technology tested commercially available flash memory products for radiation resistance as part of the Jupiter Icy Moons Explorer mission. Macronix's NOR Flash and NAND Flash products both won first place, beating international competitors such as Micron, Kioxia, and Infineon. The test results were turned into four papers and published at the RADECS (RADiation and Its Effects on Component and Systems) International Symposium in 2019 and 2021, respectively. [3]-[6]

The market share of Taiwan in global semiconductor foundry capacity increases year by year

In the past decade, Macronix's product defect rate has consistently declined (Fig. 1), while Taiwan's market share in global semiconductor foundry capacity continues to increase (Fig. 2). The sNOVA system not only has improved the product quality yield rate but also changed the structure of the global semiconductor market.

sNOVA is Taiwan’s pioneer of AI and Industry 4.0 in the semiconductor industry

The EDA system sNOVA, developed more than 30 years ago, is a pioneer in industrial automation and in introducing statistical methods and artificial intelligence to the semiconductor industry. Through decades of implementation and continuous upgrades, the spirit and concept of the sNOVA system are often seen as the foundation for Industry 4.0 development in Taiwan's semiconductor industry.

Take the defect automatic classification system as an example: from capturing photos and sampling to classifying and removing defective ICs, the whole process is completely intelligent. It not only completes the communication, connection, and data integration with existing machines or systems in the semiconductor industry but also standardizes the way engineers work, further developing AI methods to replace traditional processes [7]-[11].

Compared with traditional manual operations, the current results have increased the accuracy by four times, with the amount of defect detection being increased by more than 10 times, and work efficiency being improved by over 10 times. This operation mode exemplifies the principles of Industry 4.0, which is gaining increasing prominence today.

Inviting statistical professionals to invest in semiconductor industry applications

More than 30 years ago, for students graduating from statistics-related departments, most pursued careers in financial and insurance-related fields. At that time, it was almost unheard of for statistics graduates to work in semiconductor factories. However, the development of several generations of the sNOVA system has created a demand for statistical talent in the semiconductor industry, opening up new application fields for graduates of statistics-related disciplines. Cheng-yung PENG, a statistics expert and SPC engineer at Macronix, worked tirelessly to educate and recruit statistical talent from campuses, introducing and promoting these concepts in several universities in Taiwan [12].

As Macronix successfully integrated data analysis and statistics into production lines, sNOVA ensures that innovative methods are effective in addressing engineering problems through computer simulation and experimental verification. For example, it incorporates multivariate analysis, regression analysis, reliability analysis, and statistical verification. Notably, the semiconductor industry is critical to Taiwan's economic development, and the government has also invested significant resources and placed great importance on its advancement.

What obstacles (technical, political, geographic) needed to be overcome?

Overcoming the challenges of semiconductor’s 600-700 complex processes

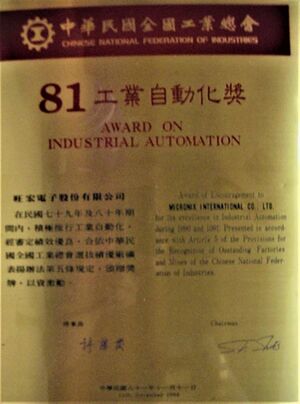

Macronix achieved an unprecedented milestone by overcoming the challenges of managing 600-700 complex semiconductor manufacturing processes. The early semiconductor production line relied on handwriting to record data such as the flows and parameters of each machine operation on "paper cards." However, the semiconductor manufacturing process often involves 600-700 complicated procedures. This traditional method was not only inefficient but also highly prone to errors. When global fabs were still operating their production lines in this traditional way, Macronix developed the earlier generations of the sNOVA system. With no precedent to follow or established model for guidance, the system was entirely independently developed, successfully integrating 600-700 complex semiconductor manufacturing processes, demonstrating the groundbreaking AI innovation capabilities of the sNOVA system. Therefore, in 1992, after three years of development of the prototype of sNOVA, Macronix was awarded the "81 Award on Industrial Automation" by the Chinese National Federation of Industries (Fig. 3) [13].

Allowing statistics, IT and engineering talents to cooperate effectively

Another obstacle in building up sNOVA is to facilitate cooperation between statisticians and semiconductor engineers unfamiliar with each other. When statistical talents first entered the fab, it was difficult for them to communicate with colleagues from IT and engineering backgrounds.

However, after continuous adaptation, Macronix gradually found common ground among the parties. In the meantime, as the sNOVA system underwent continuous upgrades and optimizations, and production data from the first three to five years were effectively utilized, more significant benefits emerged.

In 1989, Macronix established the General Engineering Department - Engineering Data Analysis Section, and in 1999, the company integrated the team into the Department of Data Value Development. The extension and optimization of the teams present how statistics and semiconductors could be seamlessly implemented together.

What features set this work apart from similar achievements?

The sNOVA concept is rooted in efforts to rival Japanese companies that had a dominant share in the global semiconductor industry. They were accustomed to rigorous work ethics and high-quality standards, but relatively less focused on using scientific methods to analyze engineering problems encountered. To compete with the highly disciplined Japanese, Macronix not only implemented "5S3U" (5S is the Japanese words for Seiri, Seiton, Seiso, Shiketsu, and Shitsuke which means Tidy, Rectify, Clean, Purifying, and Discipline; 3U means Unevenness, Unreasonableness, and Uselessness ) work code, to improve employee discipline, but also introduced statistical methods into the production process. The production lines have been fully computerized, with all production parameters controlled by computers to reduce the influence of operators.

In the early 1980s, when IBM developed its large-scale computers IBM-3090 series that were gradually used in different manufacturing fields, including semiconductors, most of the leading companies' fabs in the world were utilizing computers in parallel with traditional methods that relied on paper and cards. Macronix was founded at that time and realized that the key factors for success should be paperless and fully computerized. Therefore, when established its first fab in 1989, Macronix thoroughly implemented this policy and worked hard to solve various problems caused by paperlessness, while also getting rid of the most difficult problem of human errors in computerization.

Therefore, the differences between sNOVA system of Macronix and other similar systems are that sNOVA system drives the production lines fully computerized and all production parameters have been computer controlled to reduce the influence of operators. But other similar systems still require operators to manually log in information, making it impossible to computerize the entire production line. In addition, sNOVA's customization surpasses the user-friendliness emphasized by other similar systems; it necessitates deeper integration with workflows and work environments, allowing AI to blend naturally into daily operations and become an indispensable part of life.

In recent years, the technology of AI and Big Data has developed vigorously. Numerous products on the market now offer AI technology, but the success of the sNOVA system is not solely dependent on AI technology. "Sustainable management,” “generating value,” and “integrating workflow with environment” are the three main reasons why the sNOVA system has been able to promote effective operation for 30 years since its inception.

Sustainable development

The AI model and method of the sNOVA system can adapt to Macronix’s process technology innovations and quickly respond to changes in machine conditions to ensure that the AI measures remain accurate and effective. The sNOVA system operates with millions of various AI models on the assembly line, actively detecting abnormal models in an automated and efficient manner and correcting them promptly. It can also be updated rapidly to accommodate changes in process technology or machine conditions, ensuring that sNOVA evolves alongside manufacturing advancements and consistently contributes to product quality.

With the rapid development of information technology in the market, "how to upgrade the technology of information development in AI systems" is not only a challenge in sNOVA's investment decisions but also directly impacts the improvement of sNOVA's computing speed and cost. The development of sNOVA incorporates the most advanced component design. An AI function may include millions of lines of code, but through the use of component-based design, only a thousand lines of code are required for daily maintenance and operation. This approach greatly reduces development time and allows for greater flexibility in updates and modifications.

The early development of sNOVA evolved from IBM's IT technology software, the NOVA system. After more than 20 years of continuous research and enhancement, it has become a system entirely developed in-house by Macronix.

Creating Value

To avoid the development of AI becoming a mere formality or yielding only short-term effects, when designing and developing the sNOVA system, Macronix places significant emphasis on practical applications. In addition to making engineers willing to use this system due to the simplicity of the operation interface and workflow, the powerful effects produced after sNOVA's intervention in production also make this system naturally integrated into the entire production process. Every IC produced by Macronix today is significantly influenced and enhanced by AI. The sNOVA system is the core system in Macronix's wafer manufacturing and a key component of Macronix's manufacturing competence.

Ensuring that AI technology contributes to product quality is Macronix’s essential spirit when developing the sNOVA system, and it is also a key factor for the success of any company that is dedicated to developing an AI system. The relationship between the sNOVA system and product quality lies in the fact that it was identified as a critical issue in the production process from the outset, while all aspects such as timely feedback on the results after the use of the production line must be considered, preventing AI development from becoming a mere formality or just a short-term result. This is also the most important feature that distinguishes the sNOVA system from other AI systems.

In addition, a company must invest considerable workforce and material resources in the long term to develop AI. If the system cannot continue to contribute, its effectiveness will be greatly reduced, which indirectly affects a company’s willingness to persist in investing in AI systems. However, the difficulty lies in that the AI system is not identical to other information systems; it cannot be completed once and for all. The system must be adjusted in a timely manner in accordance with machine conditions and process changes, or AI will not be able to continue to create value.

Deep integration with workflow and environment

In response to the demands of diverse environments, "customization" is an essential aspect of AI development. However, sNOVA's customization surpasses the user-friendliness emphasized by traditional information systems; it necessitates deeper integration with workflows and work environments, allowing AI to blend naturally into daily operations and become an indispensable part of life.

For example, in traditional defect image handling, machines capture images, and humans manually identify defects. When abnormalities are detected, the goods require special handling, and a quality abnormality report is prepared for an engineer. The sNOVA defect image recognition system, by contrast, not only automates the image analysis process but also integrates seamlessly into the workflow: after the machine captures an image, sNOVA automatically initiates recognition, detects abnormalities, activates the special goods system for processing, generates a quality abnormality report, and notifies the engineer.

Over the past 30 years, the sNOVA system has evolved to integrate with various aspects of fab operations and establish an intuitive method for implementing AI. Engineers rely on sNOVA for analysis and measurement, departments use it for streamlined communication, supervisors depend on it to evaluate projects and make decisions, and new employees engage with it during training. As sNOVA becomes deeply embedded in engineers' daily work, it fully realizes the potential of AI-driven data management. This integration requires sNOVA not only to include general AI system functions but also to encompass technologies such as ERP, MES, IoT, and Tool Automation.

Why was the achievement successful and impactful?

In the 1980s, semiconductor factories in the United States and Japan used manual filling in "Run Cards" to record information about the production process. Even when computers were introduced, their role was limited to data recording. In 1989, Macronix took the lead in promoting full computerization of semiconductor factories, establishing the first paperless fab in the world. Macronix became the first in the world to apply statistics to semiconductor production and fully automate production materials.

As a result, sNOVA enabled data-driven management of non-volatile memory ROM and NOR Flash chips production, ensuring the highest quality products and maximum productivity. Macronix became the first company in the world to significantly decrease product defect rates, and to define it in parts per billion (PPB) instead of parts per million (PPM), setting a new global standard for quality in the semiconductor industry. sNOVA innovative system has been adopted and embedded in many other semiconductor fabs, enabling rapid progress in the semiconductor industry and facilitating Taiwan to play a key role in semiconductor industry worldwide.

Supporting texts and citations to establish the dates, location, and importance of the achievement: Minimum of five (5), but as many as needed to support the milestone, such as patents, contemporary newspaper articles, journal articles, or chapters in scholarly books. 'Scholarly' is defined as peer-reviewed, with references, and published. You must supply the texts or excerpts themselves, not just the references. At least one of the references must be from a scholarly book or journal article. All supporting materials must be in English, or accompanied by an English translation.

1) C.-F. Chien, S.-C. Hsu*, and J.-F. Deng, “A cutting algorithm for optimizing the wafer exposure pattern,” IEEE Trans. Semiconductor Manuf., vol. 14, no. 2, pp. 157-162, May 2001. (Submitted: Aug. 5, 2000, *: employee of the Macronix Int. Co.)

The semiconductor manufacturing industry competes by increasing yield and reducing die costs, leveraging significant capital investments. Many studies focus on defect reduction to improve yield rates; however, the optimization of wafer exposure patterns has received relatively little attention. In this paper, given specific patterning constraints, we propose a two-dimensional (2-D) cutting algorithm to maximize the gross die yields of eight-inch wafers and larger circular wafers. Empirical results implemented in a wafer fabrication factory in Taiwan demonstrate the practical viability of this approach. Similar methodologies can be readily applied to other wafer patterning processes.

2) C.-F. Chien, S.-C. Hsu*, and C.-P. Chen*, “Procedure of alignment for optimal wafer exposure pattern,” US Patent 6,368,761 B1, Filed: May 9, 2000, Issued: Apr. 9, 2002. (Assignee: Macronix Int. Co.)

Conventionally, efforts to improve the yield of chips produced on a wafer have focused on defect reduction. Another effective approach is optimizing wafer exposure patterns. The present invention introduces a computer-based procedure and apparatus to expose cells on the surface of a wafer, maximizing the number of dies produced. This invention applies to six-inch and eight-inch wafers, as well as larger wafers.

3) C.-F. Chien, K.-H. Chang, and C.-P. Chen*, “Design of a sampling strategy for measuring and compensating for overlay errors in semiconductor manufacturing,” Int. J. Prod. Res., vol. 41, no. 11, 2547–2561, 2003.

To enhance resolution and alignment accuracy in semiconductor manufacturing, it is crucial to measure overlay errors and control them within tolerances by eliminating assignable causes. Numerous studies have investigated the factors causing overlay errors, proposed mathematical models, and developed overlay error control methods. However, limited attention has been given to the sampling strategies involved. This study proposes specific designs of sampling patterns to effectively measure and compensate for overlay errors while using a practical number of samples. To validate the proposed approach, the sampling strategies were tested against empirical data from a wafer fabrication facility. The results showed that the proposed sampling patterns achieved higher goodness of fit for the overlay model and lower residuals after compensation. This paper concludes with findings and discussions on potential avenues for further research.

4) C.-F. Chien, K.-H. Chang, C.-P. Chen*, and S. L. Lin, “Overlay error model, sampling strategy and associated equipment for implementation,” US Patent 6,975,974, B2, Filed: Aug. 1, 2001, Issued: Dec. 13, 2005. (Assignee: Macronix Int. Co.)

In the manufacturing of VLSI circuits, achieving accurate overlay is a critical step. To enhance resolution and alignment accuracy in the microlithographic process, overlay errors must be measured and minimized to within acceptable tolerances. This invention introduces an overlay error model and a corresponding sampling strategy. Additionally, it includes the design of a device that leverages the model and strategy to measure overlay errors effectively.

5) C.-J. Kuo, C.-F. Chien, and J.-D. Chen*, “Manufacturing intelligence to exploit the value of production and tool data to reduce cycle time,” IEEE Trans. Automat. Sci. Eng., vol. 8, no. 1, pp. 103-111, Jan. 2011. (Submitted: June 17, 2009, Best Paper Award of the Year by IEEE RA-S)

Cycle time reduction is critical for semiconductor wafer fabrication companies to maintain a competitive edge as the industry becomes increasingly dynamic and fast-paced. According to Little’s Law, maintaining the same throughput level while reducing Work-in-Process (WIP) leads to cycle time reduction. However, existing queueing models used for predicting the WIP of tool sets in wafer fabrication facilities (fabs) face limitations in practical applications. Additionally, minimal research has been conducted on predicting the WIP of tool sets under tool dedication and waiting time constraints, which are crucial for managing WIP levels to reduce cycle time without compromising throughput, This study addresses this gap by proposing a manufacturing intelligence (MI) approach based on neural networks (NNs) to leverage the extensive production and tool data available for predicting WIP levels in tool sets. Empirical data collected from an Integrated Device Manufacturer (IDM) focused on a niche market in Taiwan was analyzed to validate this approach. The results demonstrate the practical effectiveness of the approach and its capability to identify and optimize critical input factors for reducing WIP and cycle time in fabs.

References

[1] The 5th Taiwan Presidential Innovation Award in the individual category, 2022.

In 2022, Miin Wu, chairman of Macronix, won the 5th Taiwan Presidential Innovation Award in the individual category. He was recognized as the first to integrate statistical and data mining methods to improve semiconductor process technology and production efficiency and shorten product development time. In an interview in 2022, C.C. Wei, CEO of Taiwan Semiconductor Manufacturing Co. (TSMC), said, "When everyone didn't have much knowledge of artificial intelligence, Chairman Wu had the insight that the production line could run well by integrating production information. Frankly speaking, this kind of thinking and practice was very innovative 30 years ago."

[2] Macronix High Performacne Quad SPI NOR Flash Products Power Xilinx UltraScale (TM) FPGAs for the Aerospace & Defense Market, CISION PR Newswire, 2015.

[3] Vargas-Sierra, S., Tanios, B., González-Luján, J. J., Tilhac, F., Domínguez, M., & Poivey, C. (2019, September). TID Radiation Effects of 1Gb COTS NOR Flash Memories for the ESA JUICE Mission. In 2019 19th European Conference on Radiation and Its Effects on Components and Systems (RADECS) (pp. 1-4). IEEE.

[4] Tanios, B., Kaddour, M., Forgerit, B., Guerre, F. X., & Poivey, C. (2021, September). Single Event Effects Characterization of 55-65nm NOR Flash for Space Applications. In 2021 21th European Conference on Radiation and Its Effects on Components and Systems (RADECS) (pp. 1-4). IEEE.

[5] ibid. TID Characterization of 24-45nm COTS NAND Flash for Space Applications.

[6] ibid. Single Event Effects Characterization of 24-36 nm COTS NAND Flash for Space Applications.

[7] Chien, C.-F., Hsu, S., and Chen, C. (1999), “An Iterative Cutting Procedure for Determining the Optimal Wafer Exposure Pattern,” IEEE Transactions on Semiconductor Manufacturing, 12(3), 375-377

[8] Chien, C.-F., Chang, K., and Chen, C. (2001), “Modeling Overlay Errors and Sampling Strategies to Improve Yield,” Journal of the Chinese Institute of Industrial Engineers, 18(3), 95-103

[9] Peng, C.-Y. and Chien, C.-F. (2003). Data value development to enhance competitive advantage: A retrospective study of EDA systems for semiconductor fabrication. International Journal of Services Technology and Management, 4(4-6), 365-383

[10] Chien, C.-F., Lee, P.-R., and Peng, C.-Y. (2003), “Semiconductor Manufacturing Data Mining for Clustering and Feature Extraction,” Journal of Information Management, 10(1), 63-84

[11] Tu, K. K.-W., Lee, J. C.-S., and Lu, H. H.-S., (2009), "A Novel Statistical Method for Automatically Partitioning Tools According to Engineers’ Tolerance Control in Process Improvement," IEEE Transactions on Semiconductor Manufacturing, 22(3), 373-380

[12] 13th Distinguished Alumni of the College of Science, National Tsing-Hua University - Cheng-yung PENG (graduated from Statistics Group, the Graduate Institute of Applied Mathematics in 1988), 第十三屆理學院傑出校友 - 彭誠湧學長 (應數所統計組1988). Available:https://math-alumni.site.nthu.edu.tw/p/406-1329-142593,r1389.php

[13] "81 Award on Industrial Automation", National Federation of Industries of the Republic of China,1992. Available: https://www.president.gov.tw/NEWS/26696?DeteailNo=總統創新獎

In 1992, Macronix Electronics received the "81 Award on Industrial Automation" from the National Federation of Industries of the Republic of China. The then Minister of Economic Affairs, Vincent Siew, presented the award, praising Macronix for its pioneering efforts in implementing the "Computer Integrated Manufacturing System" since its establishment in 1989, seamlessly integrating manufacturing, marketing, and management through advanced computerization.

Supporting materials (supported formats: GIF, JPEG, PNG, PDF, DOC): All supporting materials must be in English, or if not in English, accompanied by an English translation. You must supply the texts or excerpts themselves, not just the references. For documents that are copyright-encumbered, or which you do not have rights to post, email the documents themselves to ieee-history@ieee.org. Please see the Milestone Program Guidelines for more information.

Please email a jpeg or PDF a letter in English, or with English translation, from the site owner(s) giving permission to place IEEE milestone plaque on the property, and a letter (or forwarded email) from the appropriate Section Chair supporting the Milestone application to ieee-history@ieee.org with the subject line "Attention: Milestone Administrator." Note that there are multiple texts of the letter depending on whether an IEEE organizational unit other than the section will be paying for the plaque(s).

Please recommend reviewers by emailing their names and email addresses to ieee-history@ieee.org. Please include the docket number and brief title of your proposal in the subject line of all emails.